Forklift forks are known by many different names – they are also called tines while others refer to them as blades.

Now, let me ask you this first – are the forks your truck is equipped with has the right ones for the application you’re doing?

We know how essential they are inefficient and safe operation; for that reason, ensure that your forklift has the correct forks and that they are in the best condition.

In this article, not only we discussed the types of forks suitable for every use but we also gave answers to the most frequently asked questions we often hear from end-users. See below.

If you have concerns that we haven’t covered in this article, please feel free to contact us, we will try to give the best possible solution.

Types of Forks That You Can Use for Your Application

Block forks – this type is used in picking up cement and cylinder blocks. You can easily tell that it is a block fork because of its square profile. For maximum strength, its heel is forged and enlarged since it’s not as wide as the standard type. Block forks are also available in round bar design for easy, adjusting replacing and locking.

Bolt-On Forks – as its name implies, this type is fastened by bolts on the carrier instead of the standard hook and pin. With that, any movement on the laden forks significantly reduces especially when the forklift is in motion making the load handling more secure. Used primarily to handle beverages on pallets.

Coil Forks – this type used in handling and transporting steel coils and concrete pipes in the warehouse or job site. To prevent damage to the product, the edges of the blades are chamfered and the inside heel has a specific radius to protect the load from getting scratched or dented.

Tire Forks – are used for carrying tires of various sizes. This type is very identical to coil forks because the profile is chamfered as well. You have two options with this type – the tire contour and the other one is economical. If damage to the product isn’t much concern, you can opt into using the economical. They are fitted to forklift carriage with bold, and it is therefore important the holes pattern is the same as that the carriage.

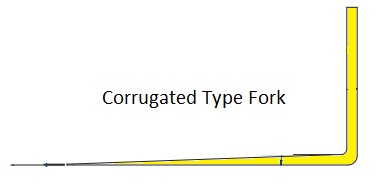

Corrugated Handling Forks – There are loads that aren’t sitting on pallets or skids, for that, corrugated handling forks are used in this application. Because it’s thin, this type is can easily wedge under and fit between the corrugated thin steel plate and floor surface. The thinness makes it easy go through to prevent damage to the product being handled.

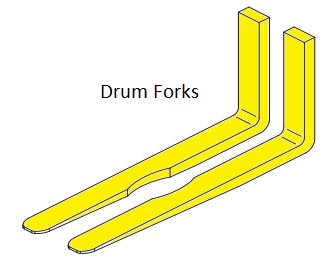

Drum Forks – As the name implies, it used for carrying 55-gallon drums. These forks are distinct because they have arc in the inside edge that matches the shape of the drum. Drum forks can also be used to carry standard loads resting on pallets or skids.

Peek-a-Boo Forks - are used dominantly in the lumber industry. The shank of this type of forks is shorter to withstand the enormous stress exerted when lifting heavy lumbers. These forks are wide but thin.

| Type | Standard Dimension | Unique Features |

| Block Forks | 2" x 2" (TxW) | can be ordered based on the required length, mounting choices are hook, tube, or floating eye |

| Bolt-On | 450mm x 180mm x 6,000mm (WxTxL) | Forks can be bolted either on the back or front of the carriage, bolt pattern must match with the carriage. |

| Coil Handling Forks | 42" Tall x 68" Long; 3.5" Thick x 7.5" Wide | can be secured using pin or pin mount, inside heel radius can be modified to prevent damage to the product |

| Corrugated Handling Forks | 3mm Tip x 4" Wide x 48" Long x 1.5" thick in the Heel | tapered fully from the top, the blade is very thin, edges of the tip are rounded |

| Gypsum Forks | up to 12" wide | Double-sided bevel at the tip to protect materials; |

| Peek-a-Boo Forks | 43" long x 2" thick (Shank is 36" | It increases the operator's visibility; it must be approved by the Engineering of the manufacturer because the contour and shape will depend on the load |

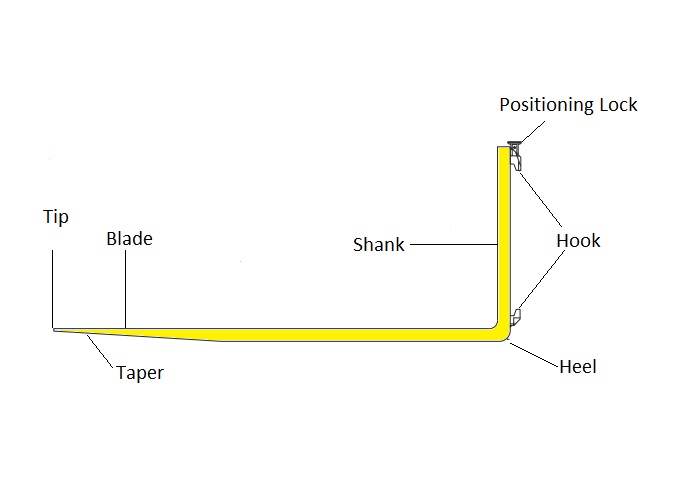

Its Basic Anatomy

Are They One-Size-Fits-All?

Unlike other accessories, the forklift forks are not one-size-fits-all attachment and therefore they’re not universal. Why is it so? Because the maximum lifting capacity of the forklift should match with fork’s capacity. You may refer to the data plate to see these specifics.

Although, you might find some models that they “say” are universal especially the ones out in the market today that are made in China but please do remember that forks to install are specific to the lifting capacity of the truck.

The forks that your forklift must equip with also depend on the specifics (the weight, dimension and load center) of the load they will be picking up. Let’s say for example if the load is 100 inches long, the ideal length of the forks to handle such load is 75 inches or that is 75% of the load’s length. If the forks are longer than the length of the load being carried, it is a safety concern as the operator can hit pedestrians or other vehicles while driving.

Kind of Steel the Forks is Made Of

The forks do the heavy lifting, it should be made from the best steel to ensure they are able to endure the maximum weight it can carry. The high-quality forks are made of high-strength boron carbon allow steel. Forklift forks can also be made of stainless steel and used primarily in food handling and pharmaceutical applications where hygiene is a top priority.

They have been heat-treated and hardened to provide high-strength metal to make them tough and exceed the quality standard set forth by the governing regulation.

You might hear that only the heels of the forks are heat-treated, yes it is true. That's why when you have to replace them, it is much better to choose the forks that are heat-treated from the tip of the blade up to the end of the shank to decrease of risk of failure when subjected to heavy load.

Conduct Inspection to Measure the Dimension for Wear

When measuring forks dimension you have to conduct first visual inspection and check for things like crack which common to happen at the heel of the fork; you also need to check the heels for wear as the operator tends to drag them on the surface creating sanding effect – to do this, you can use the cascade fork gauge.

You may also watch this video to measure the forks dimension:

How Far Apart the Forks Should Be

There are two scenarios that could happen if the forklift forks are not in correct spacing: if they too far apart, it could cause the pallet to curve and eventually break if the point of heavy contact is at the center; on the other hand, if they are too close, it may cause the pallet to become unstable during lifting and transporting.

If you’re driving a counterbalance forklift, the common type of truck, the standard distance of forks between each other is 1.2 meters. The forks should be spaced and positioned so that load will become more secure during transport. But then again, the distance will depend on the size of the pallet.

Adjusting forks manually is not an economical way especially when you have a lot of pallets of different sizes. The fork positioner is particularly useful in this circumstance; it is used to adjust the forks further apart or closer to each other using the built-in hydraulic system.

How Do I Know If They Are Bent

The number one rule when you found out that the forklift forks are bent is that it should be replaced and not repaired. Do not attempt to repair or force back it to its original shape as this may cause the weakening of the metal.

You can know if your forklift forks are bent is during a physical inspection. The bending happens either in the shank or in the blade. The forks could bend at any angle depending on where the stress or weakening on the metal is.

If the bend is minute it is hard to tell. The rule of thumb is that the angle of the forks should not exceed 93 degrees, if it is then it is a tell-tale sign that it is bent. You can use a cascade gauge to measure for the bend. In many cases, especially when the forks are worn out, the bending can easily be seen you don’t have to use the cascade gauge.

Bending is common and it is the result of exceeding the weight limit the forks can handle. The crack usually occurs together with the bend. If the operator found out about it, the issue should be reported for immediate corrective action.

Can You Weld on Forklift Forks?

If you happened to see metal cracks or wear on the surface, never repair by welding by yourself. Any issues should be reported to the qualified person to carry out the test to verify if the forks are still serviceable or not.

Under the rules, you are not allowed to weld on any part of the forks unless you’re authorized to repair under the manufacturer’s approved welding procedure.

After getting the forks repaired or welded, testing them would be ideal to verify its strength and if it is in accordance with the manufacturer’s specifications.

What everyone’s worry is if in the later time, the fork snaps or breaks, it is the person who did the repair to blame but the liability is to the owner if found out in the investigation that there’s negligence. To avoid such liability it is still suggested to have the fork certified by a testing laboratory so that when something happens, the liability is on the testing facility, not yours because they certified the repair.

It is still best recommended to have the broken fork replaced to have peace of mind it would not cause any accident.

Can You Drill Holes in It?

You can drill holes in forklift forks but not without the manufacturer’s approval. It is also recommended that the drilling should be done by the manufacturer. The reason we want the manufacturer to do this is we don’t want to compromise its strength and reach a point that it no longer meets the required standard.

Just like welding, drilling holes in the forks by yourself is a no-no. It may affect the structural integrity of the metal and could break when laden with a heavy load. The last thing you don’t want to happen on-site is an accident especially during the investigation OSHA got involved – you may face a hefty fine and serious penalty if they found out it is your fault.

When Should They Be Replaced?

There are circumstances you have to replace the forks. If one or more of these scenarios occur, it is time to have the forks replaced:

- Over the years, the forks lessen in thickness and its load capacity also diminishes. With just 10% wear on the forks, reduces its load capacity by 20%. To determine how much thickness remains, you can use a caliper. If it is verified the forks had suffered that amount of wear, they must be replaced.

- The blade and shank are the ones commonly bent and to see if they’re bent, you can use a cascade fork gauge to determine the angle. The general rule is if the angle exceeds 93 degrees, then the forks are bent. If this happens, do not bend it back to its original angle as they may weaken the forks and affects its structural integrity.

- Cracking is also common and the place to start looking for crack is at the heel where it is most likely to develop but a crack can appear on any surface of the forks. Have the forks replaced if you found cracks.

- Rest the forks on a flat surface and see the tips if they are on the same height. They should be roughly on the same level to each other. If not, check the height difference. The rule of thumb is if the difference is more than 3% of the length of the blade, then it is time to have the forks replaced. (e.g: if the length of the blade is 36”, then the height difference should not be more than 1.08”)

A word of advice: changing the forks may change your forklift’s lifting capacity and therefore before doing so, written approval from the manufacturer is required as this step is crucial in the safe operation of the vehicle. This requirement is stated in ANSI B56.1.

Ways to Prevent Damage

- The first thing to prevent early damage to your forks is not to load products with weight more than the capacity the forks can handle. See the fork’s capacity rating as it is stamped on it.

- Do not drag the heel of the forks on the surface. It creates a sanding effect and weakens the heel over time. Remember the heel receives the greatest stress so this is where most like to develop the damage (cracks, metal fatigue).

- The funny thing operators sometimes do is they lift with just one fork. The forks are to be used in tandem; lifting load with just one fork stresses the metal that could cause cracking or bending. Use both of them always!

- Never collide the forks with the racks or any structure during operation as it could damage the sensitive tip. The tip is very vulnerable to damage as it is the weakest part since it is not as thick as the taper.

- To protect the forks from damage, a routine inspection must be performed on them. Early detection of wearing and surface crack minimizes not only accidents but also further damaging the forks.

Can a Single Fork Be Replaced or Should They Be Replaced in Pairs?

Over time, with everyday use, forks diminish in thickness and that’s normal for a forklift that is subjected to heavy use. There could also be an instance when only one fork shows excessive wear. If this happens, the first thing you think is can you just replace the fork that shows signs of damage, or should they be replaced in pairs.

If you found excessive wear or severe damage in a single fork it is best practice to have both of them replaced. It is a safety issue if you just replaced a single fork - they don’t perform similarly because one is has shown excessive usage while the other is new.

If you found noticeable damage such as a crack, it is advised that only the manufacturer should make the repair (welding, heat-treatment) to ensure that the repair meets the relevant safety standard. Never ever do it yourself.

Conclusion

The forklift forks are an integral part of the equipment as they do the heavy lifting. The forklift you’re using should be equipped with the right forks for the application you’re doing. Otherwise, you’re facing the risk of an accident.

We hope we enlightened you with the answers we provided to the most frequently asked questions we heard from people.