OSHA requirements on steel toe boots are all about making sure our feet stay safe when we're working. Often, we don't think about our feet as much as we should, especially when faced with job hazards like falling objects, moving machinery, or sharp tools. But just like helmets protect our heads and gloves shield our hands, steel-toe boots are crucial for our feet.

OSHA requirements on steel toe boots are all about making sure our feet stay safe when we're working. Often, we don't think about our feet as much as we should, especially when faced with job hazards like falling objects, moving machinery, or sharp tools. But just like helmets protect our heads and gloves shield our hands, steel-toe boots are crucial for our feet.

These special boots are designed to offer an extra layer of safety against common workplace threats. Thanks to OSHA's guidelines, there's clarity on when and where these boots should be worn.

In this article, we will break down these guidelines step by step, helping both workers and employers understand why foot safety is so vital and how to ensure it in various job scenarios."

OSHA Regulations for Foot Protection

When we step into various workplaces, foot safety often emerges as a paramount concern. The Occupational Safety and Health Administration (OSHA) recognizes this and has established regulations to ensure that workers' feet are adequately protected against numerous potential hazards.

General PPE Requirements - 29 CFR 1910.132

Before diving specifically into foot protection, it's essential to understand OSHA’s broader guidelines on Personal Protective Equipment (PPE). As outlined in 29 CFR 1910.132, the general requirements state that:

Employers must assess their workplace to determine if hazards are present, or are likely to be present, which necessitate the use of PPE.

If such hazards are identified, the employer must select, and have each affected employee use, the type of PPE that will protect the workers from the hazards identified.

The employer must communicate the selection decisions to each affected employee and ensure that the PPE properly fits each worker.

Foot Protection - OSHA 29 CFR 1910.136

Zooming in on foot protection, 29 CFR 1910.136 specifically addresses the need for protective footwear. The main points from this regulation include:

Protective footwear must comply with specific consensus standards such as ASTM F2412-05, ASTM F2413-05, ANSI Z41-1999, or any other recognized standard that offers equal or better protection.

Each affected employee must wear protective footwear when working in areas where there is a danger of foot injuries.

Mandatory Use of Protective Footwear

OSHA doesn't simply provide guidelines; it mandates them. One of the critical mandates is that employers ensure employees wear appropriate foot protection if their roles expose them to risks such as:

- Electrical hazards: This can range from static electricity build-up to the risk of electric shocks.

- Hot, corrosive, or poisonous substances: These can cause burns, chemical reactions, or other harm upon contact.

- Falling objects: This refers to any item that could drop on a worker's foot, potentially causing injury.

- Crushing or penetrating actions: These can come from machinery, tools, or even vehicular movement.

- Other similar workplace hazards that pose a foot injury risk.

In essence, OSHA's regulations underscore the importance of foot safety and aim to ensure that every step taken in a workplace is a protected one.

OSHA 29 CFR 1917.96(b)

This specific regulation stipulates that:

- Employer's Responsibility Regarding Payment: The employer is not mandated to cover the costs of "non-specialty safety-toe protective footwear" (which includes commonly available steel-toe shoes or boots) or "non-specialty prescription safety eyewear."

- Condition for Not Paying: The above point holds true only if the employer allows employees to use these items (the footwear and eyewear) outside of the job-site. The rationale behind this is that if the items can be used both on and off the job (i.e., they are not specialized solely for job-related tasks), then the employer isn't strictly obligated to bear the cost. However, this might vary based on collective bargaining agreements or other employment agreements in place.

This regulation is part of OSHA's larger set of rules about the provision and payment for PPE. The goal of these rules is to ensure that workers are provided with or have access to, the necessary equipment to protect them from job-related hazards.

If an employer mandates specific specialty safety equipment that cannot reasonably be used outside of the job site, then the employer would generally be responsible for providing or paying for it.

It's also worth noting that while OSHA sets federal standards, individual states might have their own occupational safety and health regulations which can be stricter than OSHA's. Always good to check on both federal and state-specific regulations when considering compliance.

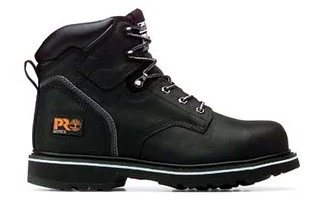

The Steel-Toe Boots Must Adhere to These Specifications

- Leather Tops: Leather is commonly used in safety footwear due to its durability, flexibility, and natural resistance to some environmental factors. It also offers some protection against incidental contact with live electrical conductors.

- Oil-Resistant and Non-Skid Soles: These are crucial in many work environments, especially where workers might encounter slick surfaces due to oil or other lubricants. Non-skid soles can prevent slips and falls, a major concern in many workplaces.

- ASTM F2413-05 Standard: The ASTM F2413 standard addresses the minimum requirements for design, performance, testing, and classification of protective footwear. An impact resistance of 75 means the toe cap can withstand an impact of up to 75 pounds, and a compression resistance of 75 indicates that the shoe will protect against compressive loads up to 2,500 pounds. These numbers give a clear idea of the level of protection the shoe offers.

- Electric Shock Resistance (ESR): This is a crucial specification for those in the electrical trades or anyone working around live electrical circuits. Boots that are resistant to electric shocks have soles and heels designed to reduce the risk of the wearer completing an electrical circuit to the ground, thus preventing electrical shock. This does not mean the shoes are entirely non-conductive, but rather they reduce the risk of electric shock.

When selecting a pair of safety shoes that meet these specifications, it's crucial to:

- Consult with trusted suppliers or manufacturers: There are numerous brands and manufacturers that offer safety shoes that meet these specifications. Research and consultation can help you find the right fit.

- Consider Comfort: Safety is paramount, but don't overlook comfort. If the shoes are uncomfortable, employees might be less inclined to wear them consistently, negating their protective value.

- Regularly Inspect and Replace: No matter how durable, safety shoes wear out and should be inspected regularly for signs of wear, damage, or other issues. Any compromised footwear should be replaced promptly to ensure ongoing protection.

How About Those Workers Working in the Electrical Trade

The primary goal of OSHA is to ensure that employers provide their employees with a safe and healthful work environment. When it comes to specific trades like the electrical trade, there are potential risks that workers might face, and it's up to the employer to assess those risks and determine the appropriate personal protective equipment (PPE) to mitigate them.

Safety-toe shoes, specifically steel-toe shoes, are designed to protect the toes against impacts and compressions. However, given their conductive nature, there's a concern in electrical environments about the potential for electrical conduction, which could endanger the worker.

That said, as you mentioned, OSHA generally does not consider the wearing of steel-toe shoes by electrical tradesmen as hazardous as long as the conductive portion of the shoe is isolated both from the employee's foot and from the external environment. However, for added assurance, non-metallic safety footwear that provides impact protection while also being non-conductive can be a preferable choice. This provides a dual benefit of protecting the feet from both physical impacts and electrical hazards.

While OSHA may not specifically mandate the type of safety footwear for electrical tradesmen, it is in the best interest of the employer and the employee to make informed decisions based on the specific risks associated with their work environment. This might involve consulting with PPE suppliers, considering the nature of the work, and potentially seeking guidance from safety professionals.

Factors to Consider When Selecting Steel Toe Boots

Selecting the right steel-toe boots is more than just about finding a pair that fits. It's about ensuring that they offer the protection required for the specific job role while also providing comfort for daily wear. With a myriad of choices available in the market, how does one decide which pair is the most suitable? Here are some primary considerations:

Type of Hazard Present

- Chemical Exposure: If your job involves handling or being around chemicals, it's essential to choose boots that offer chemical resistance. Special coatings or materials can resist specific chemical compounds, ensuring your feet are not affected.

- Electrical Hazards: For those who work around electricity or electrical equipment, boots that provide electrical insulation are crucial. Look for the Electrical Hazard (EH) rating on boots.

- Sharp Objects: Jobs that involve walking over sharp objects, like nails or shards, require boots with puncture-resistant soles.

- Heavy Objects: In environments where there's a risk of heavy objects falling or rolling over feet, opt for boots that provide maximum compression and impact protection.

Comfort and Ergonomic Considerations

- Fit: A good fit is crucial. Too tight or too loose can lead to discomfort or even injuries.

- Insole and Arch Support: Considering that workers might wear these boots for extended periods, good insole cushioning and proper arch support are essential to prevent foot fatigue.

- Breathability: Ventilation can help reduce sweat and odor, offering a more comfortable experience.

- Material Considerations

- Leather: Often chosen for its durability and protection. It's also breathable and molds to the wearer's foot shape over time.

- Synthetic: These are generally lighter than leather and can be more breathable, but they might not offer the same level of protection or longevity.

- Waterproofing: For environments where exposure to water or other liquids is common, waterproof or water-resistant boots are a must.

Regular Inspection and Replacement

- Wear and Tear: Over time, even the best steel-toe boots will show signs of wear and tear. Regularly inspect for damaged soles, broken steel caps, or compromised material.

- Replacement: Don't wait for a boot to fall apart completely. If there's visible damage or if the boot no longer offers the same level of comfort and support, it's time for a replacement.

The Employer's Responsibility

Workplace safety is a shared commitment, but employers bear the primary responsibility for creating and maintaining a safe environment. When it comes to foot protection, here's what's expected of employers:

- Providing PPE at No Cost: Employers are obligated to provide Personal Protective Equipment (PPE), including steel toe shoes, to employees without charging them for it. The equipment should also be of high quality and adhere to safety standards.

- Training Employees: It's not enough to simply provide PPE. Employers must ensure that employees know how to wear, care for, and use the equipment properly to get the maximum benefit.

- Assessment of Workplace Hazards: Regular evaluations of the workplace are necessary to identify potential hazards. Once identified, employers should then determine the appropriate level of foot protection required for various job roles.

Benefits of Adhering to OSHA’s Requirements

Ensuring a workplace aligns with OSHA's standards isn't just a regulatory necessity; it comes with tangible benefits:

- Reduction in Workplace Injuries: Proper foot protection reduces the likelihood of foot-related injuries, keeping workers safe and productive.

- Improved Worker Morale: When employees see that their safety is a priority, they are more likely to be satisfied and motivated in their roles.

- Financial Savings: Fewer injuries mean fewer workers' compensation claims, reduced medical expenses, and less downtime.

- Company Reputation: Companies known for prioritizing employee safety can enjoy a positive reputation, which can help in attracting and retaining top talent.

Common Misconceptions about Steel Toe Boots

Let's tackle some widespread myths about these boots:

- Myth: Steel-toe boots can amputate your toes in an accident.

- Reality: This is a common misconception. In reality, steel-toe boots are designed to protect your feet. While the steel might get dented upon severe impact, it's less likely to cause amputation compared to if the heavy object had directly landed on an unprotected foot.

- Myth: Steel-toe boots are uncomfortable for daily wear.

- Reality: Comfort depends on the quality and fit of the boot. With advancements in design and materials, many modern steel-toe boots are as comfortable as regular shoes. It's all about finding the right pair!

- Myth: All steel-toe boots offer the same level of protection.

- Reality: While all steel-toe boots provide a basic level of protection, different boots are designed for various hazards. It's essential to select a pair based on the specific risks of your workplace.

In the end, the right knowledge and adherence to safety standards can make workplaces safer and more productive for everyone involved.

To Make a Conclusion

Safety at work is a top priority, and OSHA requirements on steel-toe boots highlight this importance. These guidelines aren't just about checking off a list; they're about making sure workers go home safely at the end of the day. When we think of protection, these boots might seem like a small detail, but they can be the difference between a close call and a serious injury. By understanding and following OSHA's requirements, employers not only meet standards but also send a clear message that they value their team's well-being. In the world of workplace safety, boots stand as a testament to proactive protection, reminding us that every safe step counts.